This section introduces the Suzuki Battery Isolator Lead Voltage Output, focusing on its role in managing dual battery systems and ensuring proper voltage distribution for optimal performance and longevity.

1.1 Overview of the Suzuki Battery Isolator System

The Suzuki Battery Isolator System is designed to manage power distribution between multiple batteries, ensuring proper charging and isolation. It prevents overcharging of the starting battery while allowing auxiliary batteries to charge when the engine is running. This system is crucial for maintaining optimal battery health and performance in Suzuki outboard engines and motorcycles. The isolator lead plays a key role in this setup, enabling seamless communication between the alternator and batteries. By isolating the starting battery from auxiliary loads, it ensures reliable engine starting and prevents deep discharging. This system is particularly beneficial for boats and vehicles with high electrical demands, providing a balanced and efficient power management solution.

1.2 Importance of Voltage Output in Battery Isolation

The voltage output in Suzuki’s battery isolation system is critical for maintaining proper battery health and performance. It ensures that each battery receives the correct charge level, preventing overcharging or undercharging. A stable voltage output also safeguards against electrical system damage, which can occur from excessive or insufficient power. This is particularly vital for auxiliary batteries used to power trolling motors or electronics, as consistent voltage ensures reliable operation. Additionally, accurate voltage output helps extend battery lifespan by preventing deep discharges and thermal stress. Monitoring and maintaining optimal voltage levels is essential for the overall efficiency and longevity of the dual battery setup in Suzuki applications.

1.3 Purpose of the PDF Guide

This PDF guide is designed to provide comprehensive insights into the Suzuki Battery Isolator Lead Voltage Output system. It aims to help users understand the functionality, installation, and maintenance of the isolator lead, ensuring optimal performance. The guide covers voltage output analysis, troubleshooting common issues, and compatibility recommendations. It serves as a valuable resource for both novice and experienced users, offering step-by-step instructions and expert tips. By following this guide, users can ensure their battery systems operate efficiently, prolong battery lifespan, and avoid potential electrical damage. The PDF is tailored to address specific Suzuki models, making it an essential tool for anyone working with dual battery setups in their vehicles or marine applications.

Understanding the Suzuki Battery Isolator Lead

The Suzuki Battery Isolator Lead is a critical component designed to manage and regulate voltage output between multiple batteries, ensuring proper charging and system performance.

2.1 What is a Battery Isolator Lead?

A Battery Isolator Lead is a component designed to regulate and manage voltage output between multiple batteries in a dual battery system. Its primary function is to ensure that the starting battery is prioritized for engine operation while the auxiliary battery is charged when the alternator is active. This setup prevents over-draining of the starting battery and ensures reliable engine performance. The isolator lead effectively splits the alternator’s output, allowing both batteries to receive charge without interfering with each other. This system is commonly used in Suzuki outboard engines and motorcycles to maintain optimal battery health and performance. Proper installation and configuration are essential for its functionality.

2.2 How the Auxiliary Charging Lead/Isolator Works

The Auxiliary Charging Lead/Isolator functions by managing the flow of electrical current between the alternator and two batteries in a dual battery system. It ensures the starting battery is prioritized for engine operation, while the auxiliary battery is charged when the alternator is active. The isolator uses voltage-sensing technology to monitor the state of both batteries and directs the alternator’s output accordingly. When the engine is running, the isolator allows the alternator to charge both batteries simultaneously. However, when the engine is off, it isolates the batteries to prevent unintended drain. This system ensures efficient charging, maintains battery health, and prevents over-draining of the starting battery, making it essential for Suzuki outboard engines and motorcycles.

2.3 Types of Suzuki Battery Isolator Leads

Suzuki offers various types of battery isolator leads designed for different applications and battery configurations. The standard isolator lead is compatible with dual battery systems, ensuring proper voltage distribution. Heavy-duty isolator leads are built for high-current demands, suitable for larger engines and trolling motors. Additionally, Suzuki provides specialized isolator leads for AGM and lithium battery setups, optimizing charging efficiency. Each type is engineered to prevent overcharging and ensure reliable performance. Part numbers like SUZ-33830-98J11 are commonly referenced for specific Suzuki outboard and motorcycle models, ensuring compatibility and optimal functionality. These leads are designed to maintain battery health and provide consistent power output for all electrical systems.

Voltage Output Analysis

Voltage output analysis for Suzuki battery isolator leads involves monitoring and understanding the normal voltage range, typically around 14.7V at idle, and factors affecting it, like engine speed.

3.1 Normal Voltage Range for Suzuki Batteries

The normal voltage range for Suzuki batteries typically falls between 12.6V and 14.7V. At idle, a fully charged battery usually reads around 12.6V, while charging at higher RPMs can reach up to 14.7V. This range ensures optimal performance and longevity of the battery. Monitoring voltage levels is crucial, as deviations from this range can indicate issues such as charging system malfunctions or battery health problems. Proper voltage levels are essential for maintaining the integrity of the electrical system and preventing damage to sensitive components. Regular checks with a multimeter can help identify any abnormalities early on.

3.2 Voltage Drop at High RPM

A slight voltage drop at high RPM is normal, typically decreasing from 14.7V at idle to around 14.5V at 4000 RPM. This occurs as the alternator’s capacity is tested, and electrical demand increases. Such a drop is usually within safe ranges and doesn’t harm the system. However, excessive drops below 14V may indicate issues like a failing alternator, poor connections, or high resistance in the wiring. Monitoring voltage levels at high RPM helps identify potential problems early, ensuring reliable performance and preventing damage to electrical components. Regular testing with a multimeter is recommended to maintain optimal voltage output and system health.

3.3 Voltage Testing with a Multimeter

Voltage testing with a multimeter is essential for diagnosing the Suzuki battery isolator system. Set the multimeter to DC voltage mode and connect the leads to the battery terminals. Ensure the engine is off for a resting voltage reading, which should be around 12.6V. With the engine running, measure the voltage at the battery terminals; a normal charging voltage is approximately 14.7V. At high RPM, the voltage may slightly drop to 14.5V, which is still within acceptable ranges. If the voltage falls below 14V, it may indicate a problem with the alternator or charging system. Regular testing helps identify issues early, ensuring optimal performance and longevity of the battery and electrical components.

Installation and Setup

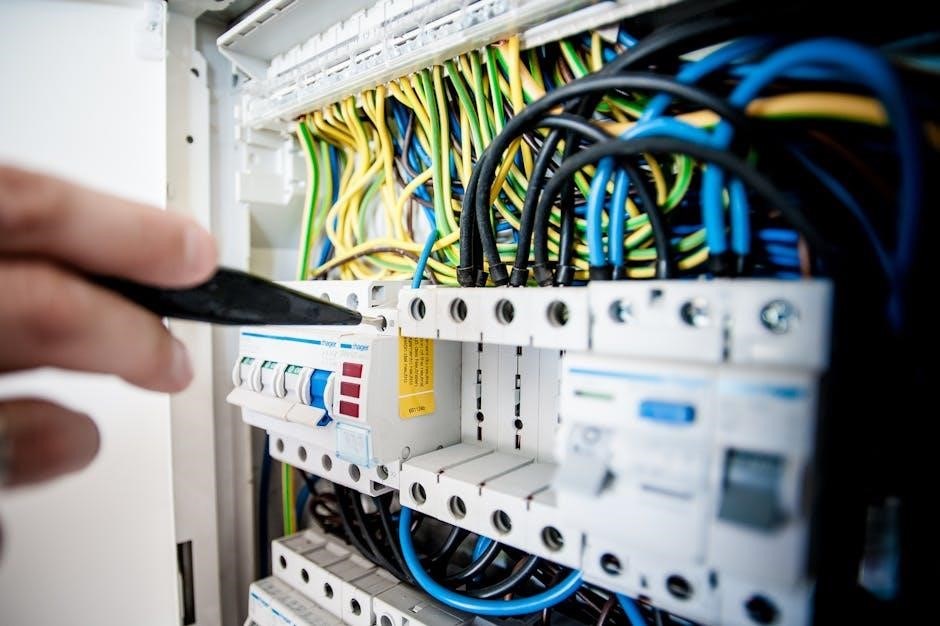

Proper installation of the Suzuki battery isolator lead ensures reliable voltage output and system performance. Connect the auxiliary charging lead correctly and configure the fuse setup according to specifications.

4.1 Step-by-Step Installation Guide

Installing the Suzuki battery isolator lead requires careful planning and execution. Begin by disconnecting the batteries to ensure safety. Mount the isolator lead securely, following the manufacturer’s specifications. Connect the lead to the alternator and battery terminals, ensuring proper polarity. Install a fuse holder and fuse, routing the wires neatly. Finally, test the system by starting the engine and monitoring voltage output with a multimeter. This step-by-step process ensures a reliable and efficient dual battery setup for optimal performance and longevity of your Suzuki outboard or motorcycle system.

4.2 Connecting the Auxiliary Charging Lead

Connecting the auxiliary charging lead involves linking the isolator to the secondary battery, ensuring proper voltage distribution. Start by disconnecting both batteries to prevent electrical surges. Locate the isolator lead and attach it to the auxiliary battery’s positive terminal. Securely connect the other end to the isolator unit. Ensure the lead is routed away from heat sources and moving parts. Install a fuse holder and appropriate fuse near the auxiliary battery for added protection. Finally, reconnect the primary battery and test the system by starting the engine and monitoring voltage output with a multimeter. This setup allows the alternator to charge both batteries safely and efficiently. Always follow Suzuki’s specifications for optimal performance.

4.3 Fuse Setup and Configuration

Proper fuse setup is crucial for protecting the auxiliary charging system; Select a fuse with a rating that matches the maximum current expected from the alternator. Install the fuse holder close to the auxiliary battery to minimize voltage drop. Connect the fuse inline with the auxiliary charging lead, ensuring it is easily accessible for inspection. Use high-quality, marine-grade fuses to withstand harsh environments. After installation, test the system by starting the engine and monitoring the voltage output. Ensure the fuse does not blow under normal operating conditions. Always refer to Suzuki’s specifications for recommended fuse ratings and configurations to maintain system integrity and safety.

Compatibility and Recommendations

Suzuki recommends using approved battery types for optimal performance. Avoid incompatible configurations to prevent system issues. Always follow Suzuki’s guidelines for battery selection and setup.

5.1 Suzuki-Approved Battery Types

Suzuki recommends using high-quality, marine-grade batteries designed for dual-purpose starting and deep-cycle applications. Lead-acid batteries are preferred for their reliability and compatibility with Suzuki systems. AGM batteries, while offering superior performance in some cases, are not recommended for larger Suzuki outboard engines due to charging requirements. Always ensure the battery meets the specified Cold Cranking Amps (CCA) and reserve capacity (RC) ratings for your engine. Using approved battery types ensures optimal performance, prevents system damage, and maintains warranty validity. Consult your owner’s manual or a Suzuki dealer for the most suitable battery for your specific model. Proper battery selection is crucial for reliable operation and longevity.

5.2 AGM vs. Lead-Acid Batteries for Suzuki Engines

When choosing a battery for Suzuki engines, it’s important to consider the differences between AGM (Absorbent Glass Mat) and traditional lead-acid batteries. AGM batteries offer superior performance in deep-cycle applications, longer lifespan, and better resistance to vibration. However, Suzuki does not recommend AGM batteries for larger outboard engines due to specific charging requirements. Lead-acid batteries are preferred for their compatibility, reliability, and cost-effectiveness. They provide consistent starting power and meet the specifications for most Suzuki engines. Always consult your owner’s manual to ensure the chosen battery type aligns with your engine’s needs for optimal performance and system compatibility.

5.3 Avoiding Incompatible Battery Configurations

Ensuring compatibility between your battery configuration and Suzuki’s electrical system is crucial for optimal performance and longevity. Mixing battery types, such as AGM and lead-acid, can lead to voltage imbalances and system malfunctions. Suzuki recommends using lead-acid batteries for most engines due to their proven compatibility and charging characteristics. Always adhere to the specifications outlined in your owner’s manual to avoid potential damage to your alternator or electrical components. Improper configurations can result in reduced charging efficiency, erratic voltage output, and premature battery failure. Prioritize system harmony by selecting batteries that align with Suzuki’s approved standards for reliable operation and extended service life.

Troubleshooting Common Issues

Diagnose voltage irregularities, address loose connections, and resolve voltage drop problems to ensure optimal performance and prevent system damage. Regular checks can help identify issues early.

6.1 Diagnosing Voltage Irregularities

Voltage irregularities in the Suzuki battery isolator system can be identified using a multimeter. Check the battery terminals, isolator lead connections, and alternator output. Common issues include voltage drops, overcharging, or undercharging. Measure the voltage at the battery terminals with the engine running and at high RPM to detect fluctuations. If the voltage drops below 13.5V or exceeds 14.7V, it may indicate a faulty alternator, corroded connections, or a malfunctioning isolator lead. Addressing these issues promptly prevents battery damage and ensures reliable engine performance. Regular testing helps maintain system health and avoids sudden failures. Always follow proper safety protocols when working with electrical systems.

6.2 Fixing the Auxiliary Charging Lead Connection

To fix issues with the auxiliary charging lead connection, start by inspecting the lead and connections for damage or corrosion. Clean any corroded terminals using a wire brush and apply a rust inhibitor. Ensure the lead is securely connected to both the starting and auxiliary batteries. Check the fuse setup to confirm it is properly configured and not blown. If the issue persists, use a multimeter to test the circuit for continuity and voltage drop. Replace the auxiliary charging lead if it shows signs of damage or fails testing. Always refer to the Suzuki service manual for specific connection procedures and recommendations.

6.3 Resolving Voltage Drop Problems

Voltage drop issues in the Suzuki battery isolator lead can often be resolved by identifying and addressing the root cause. Start by using a multimeter to measure the voltage drop across the isolator lead and connections. If the drop exceeds 0.5 volts, inspect the lead for damage or corrosion. Clean or replace the lead if necessary. Ensure all connections are tight and free of corrosion. Upgrading to a heavier-gauge cable can reduce resistance and minimize voltage loss. Additionally, verify that the alternator output matches the system requirements. If issues persist, consult the Suzuki service manual for specific troubleshooting procedures and recommendations to ensure optimal performance.

Maintenance and Care

Regularly inspect the Suzuki battery isolator lead for damage or corrosion. Clean connections to ensure proper conductivity and prevent voltage drop issues over time.

7.1 Regular Battery Maintenance Tips

Regular maintenance ensures optimal performance and longevity of Suzuki batteries. Always check voltage levels, ensuring they fall within the normal range of 12.4-12.7 volts when idle. Clean terminals and connections to prevent corrosion and voltage drop. Avoid deep discharges, as they can reduce battery life. Use a high-quality charger compatible with your battery type, whether AGM or lead-acid. Monitor charging cycles and avoid overcharging, which can damage cells. Inspect the battery isolator lead for signs of wear or damage, replacing it if necessary. Proper storage in a cool, dry place is crucial during off-seasons to maintain health and readiness for use.

7.2 Cleaning and Inspecting the Isolator Lead

Regular cleaning and inspection of the Suzuki battery isolator lead are essential for maintaining reliable voltage output. Use a wire brush to remove corrosion from the terminals and connectors. Ensure all surfaces are clean and free of debris. Inspect the lead for signs of wear, cracks, or damage, which can cause voltage drop or irregularities. Use a multimeter to test the lead’s resistance and ensure proper connectivity; If any damage is detected, replace the lead immediately to prevent system malfunctions. This routine will help maintain optimal performance and ensure the isolator functions as intended, providing consistent power distribution to both batteries.

7.3 Storage Recommendations for Suzuki Batteries

Proper storage of Suzuki batteries is crucial to maintain their health and performance. Store batteries in a cool, dry place away from direct sunlight and moisture. Ensure the battery is fully charged before storage to prevent deep discharge, which can reduce its lifespan. Use a trickle charger to maintain the charge level during extended storage periods. Avoid storing batteries in freezing temperatures, as this can cause internal damage. Regularly check the voltage and terminals for corrosion. For long-term storage, disconnect the battery from the isolator lead to prevent drain. Follow these guidelines to preserve battery capacity and ensure reliable performance when back in use.

8.1 Summary of Key Points

8.2 Final Tips for Optimal Performance

For optimal performance, ensure the Suzuki battery isolator lead is correctly installed and configured. Regularly test voltage levels using a multimeter to confirm stability. Avoid using AGM batteries for cranking in larger outboard engines, as Suzuki recommends lead-acid types. Always use Suzuki-approved battery isolator leads to maintain reliability. Clean connections periodically to prevent voltage drop issues. Monitor battery health and replace worn-out cells promptly. Keep the system well-maintained to ensure efficient charging and isolation. By following these guidelines, you can maximize the longevity and functionality of your Suzuki battery isolator lead system, ensuring seamless operation across all conditions.